At our company, we take proactive measures to optimize solder paste stencils, ensuring precise application and reducing soldering issues:

1. Stencils Made of Fine-Grained Sheet Metal: Using fine-grained sheet metal for stencils can result in more precise and consistent solder paste application. This is likely to improve the overall soldering quality and reduce defects.

2. Increasing Stencil Thickness for GSM Chips: GSM (Global System for Mobile Communications) chips may require thicker stencils to ensure an adequate amount of solder paste is deposited. This adjustment helps to avoid soldering issues with these components.

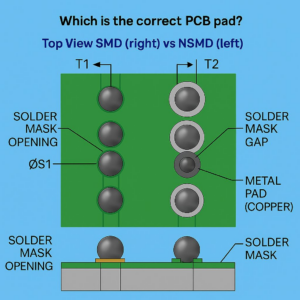

3. Grading Stencil Thickness for BGA Chips and 0201 Components: Stencil thickness may need to be adjusted based on the specific components being soldered. Larger BGA (Ball Grid Array) chips and smaller 0201 components have different soldering requirements. Adapting stencil thickness accordingly is a smart strategy for optimizing solder paste application and reducing defects.

These optimizations demonstrate a proactive approach to ensure a high-quality soldering process, ultimately leading to improved product reliability and reduced rework or defects.