In PCB manufacturing, the smallest details can make a huge difference. One effective way to prevent warping, twisting, or stress-related defects is by using non-functional pads.

When should you use them?

When your design includes components sensitive to process conditions, such as BGA

How do they help?

– stiffen the PCB structure,

– ensure even heat distribution in the reflow oven, reducing the risk of shorts under complex components,

– minimize thermal stress during cooling, preventing defects like cold solder joints in the final product.

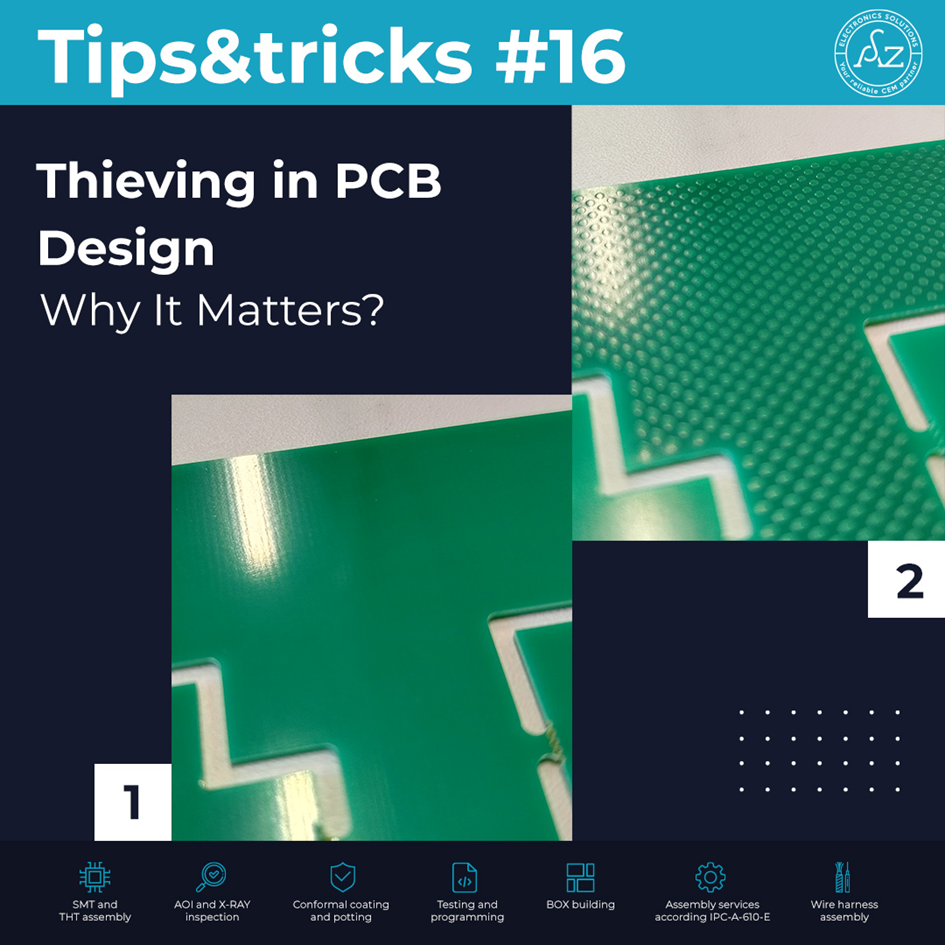

See the images below:

📷 (1) PCB without non-functional pads

📷 (2) PCB with non-functional pads