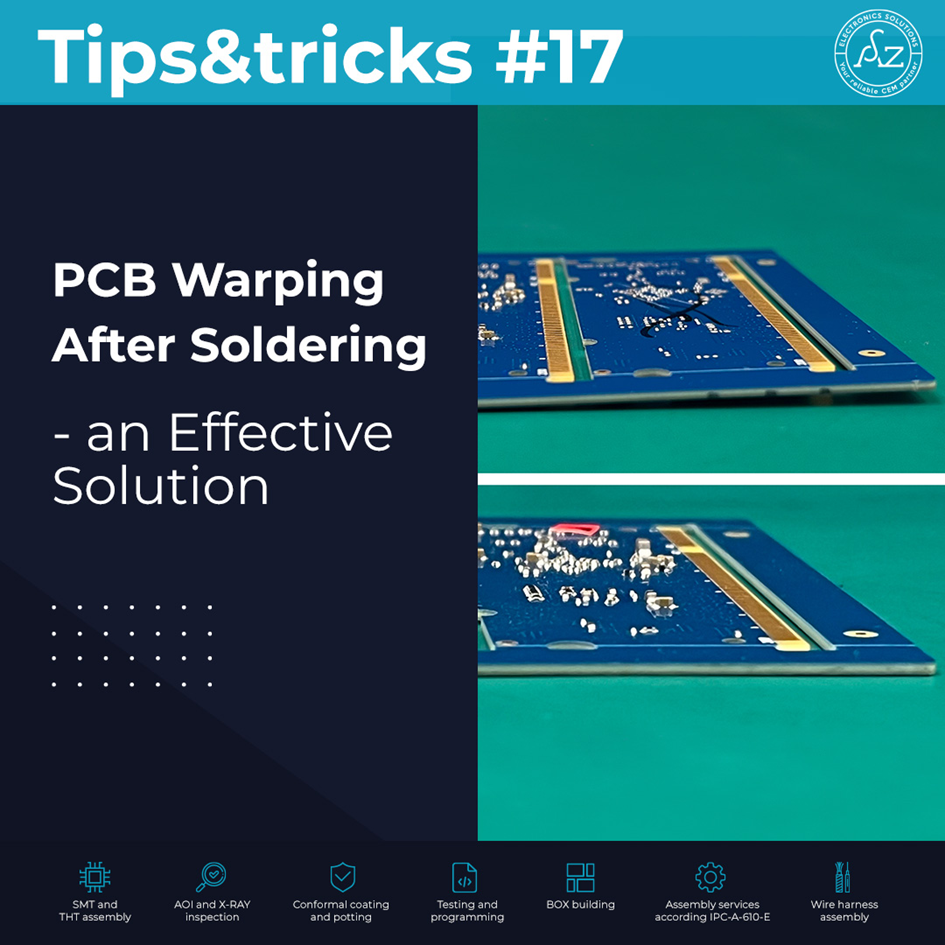

During the SMT assembly process, it may happen that the PCB becomes warped after soldering the bottom side. This deformation can significantly hinder – or even prevent – proper placement of components on the top side.

Such warping may result from uneven thermal stress distribution or specific material properties of the laminate.

A proven and efficient method to restore the flatness of the board is to run it through the reflow oven again using a standard adhesive mounting thermal profile.

This process helps to replanarize the PCB and prepare it for the next assembly stage – the results are clearly visible in the photos.

It’s a simple corrective action worth implementing in your production flow when facing similar challenges.