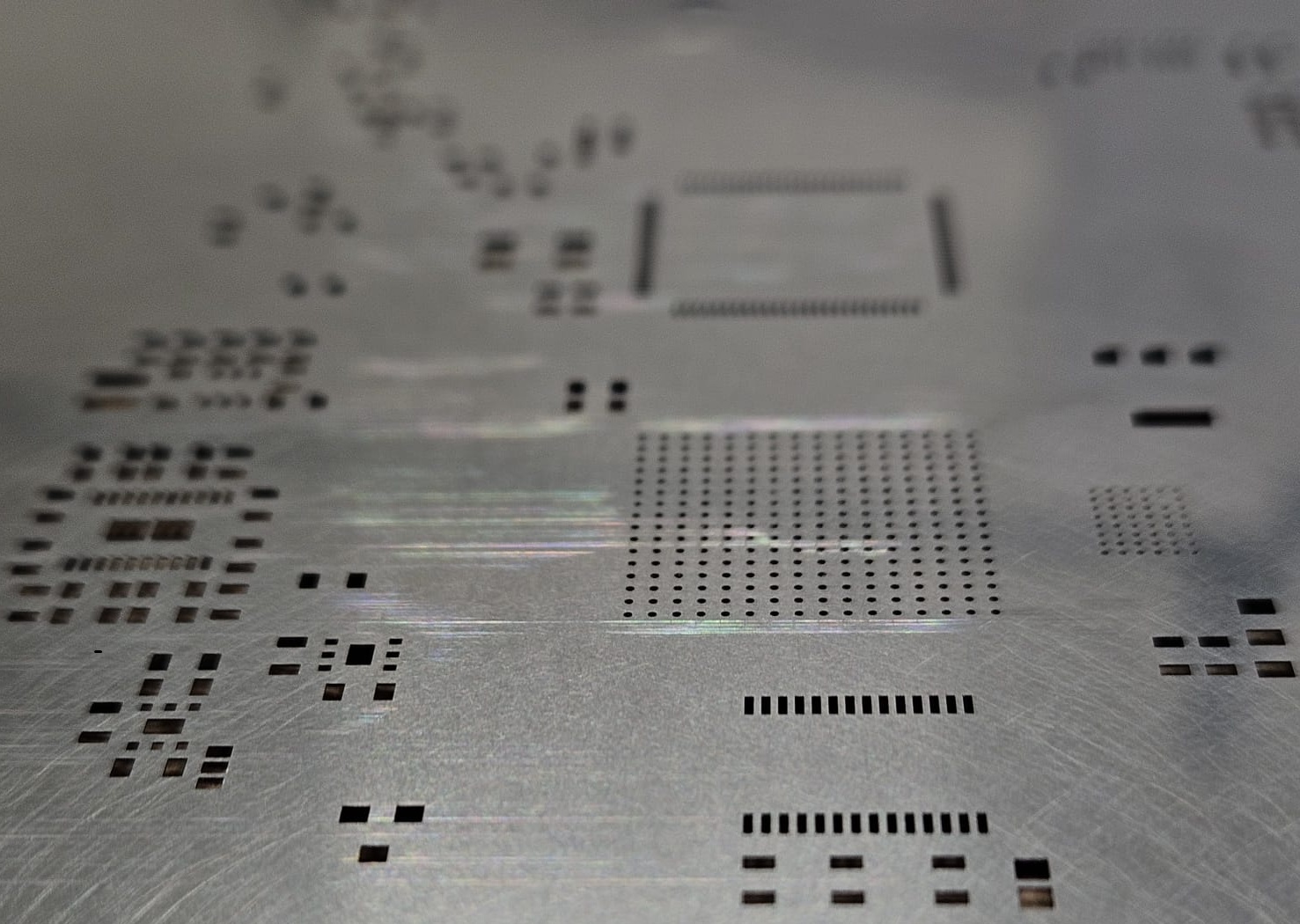

The quality of the stencil used for solder paste application has a surprisingly strong impact on the effectiveness of the SMT assembly process. It is estimated that up to 60% of assembly defects originate solely from an incorrect solder paste print.

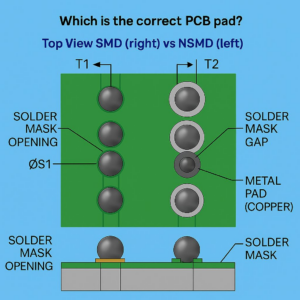

Stencil thickness and the geometry of laser-cut apertures determine the amount of solder paste deposited onto PCB pads. Equally important, however, are properly designed PCBs and footprints, which are often the root cause of SMT assembly issues.

1. Micro-welded stencils

Micro-welding involves precisely cutting openings in the base stencil and then welding in dedicated, pre-cut metal inserts. This method ensures high repeatability and precision of the apertures.

2. Milled stencils

Additional milling of laser-cut apertures allows achieving:

- stencil thickness accuracy of ±5 μm,

- step height differences of up to 400 μm.

This technology minimizes the risk of residual paste remaining inside the apertures and improves the consistency of the printing process.

3. SMT stencils with nanocoatings

Nanocoatings significantly enhance paste release from apertures — especially in very small or densely packed openings.

There are two available coating techniques:

- Manually applied nanocoating — using a cloth soaked with an active nanomaterial.

- Permanent CVD coatings — applied to the metal surface to ensure long-lasting resistance to paste adhesion.

Summary

Choosing the right stencil type and manufacturing method is a key part of ensuring high-quality SMT processes.

The right stencil = fewer defects, better repeatability, and lower rework costs.