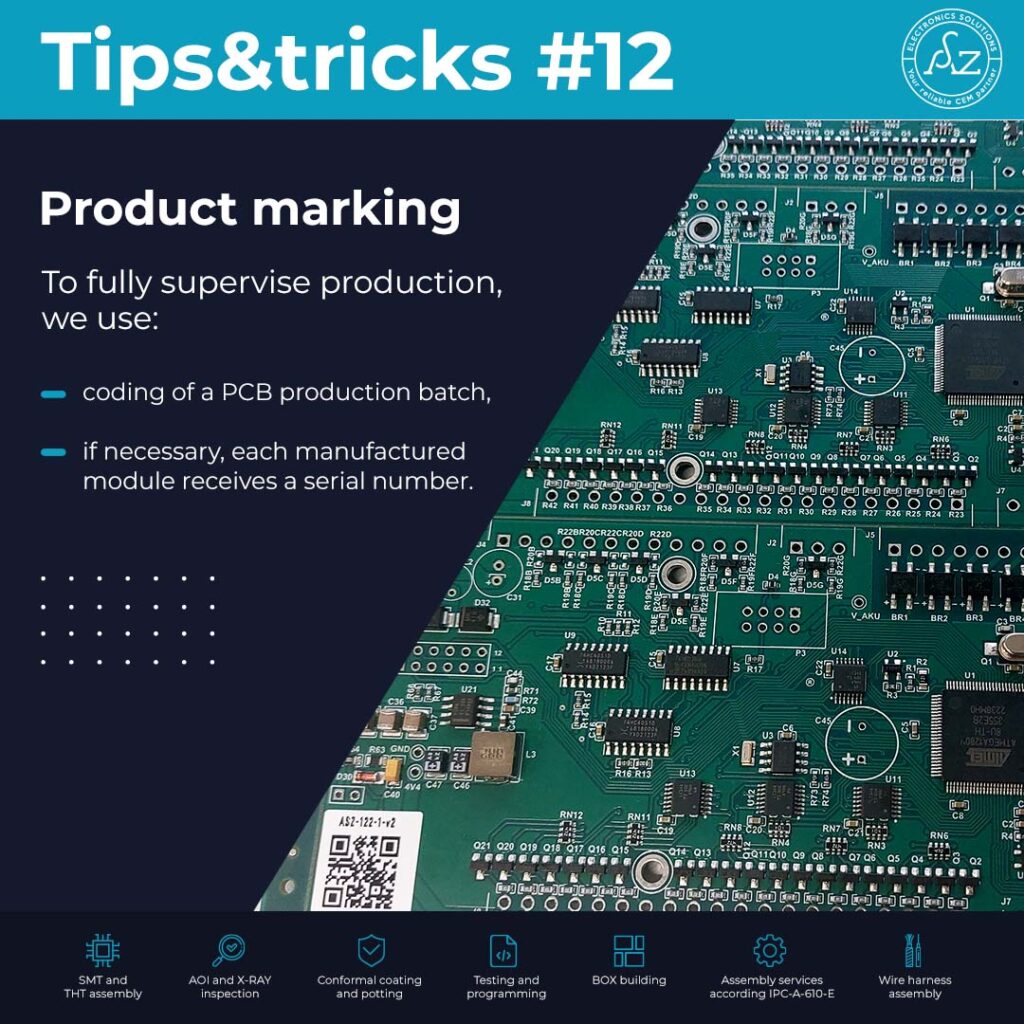

In the electronics manufacturing process, precise product marking plays a key role in ensuring full traceability and quality control. With a proper marking system, each PCB can be quickly linked to its specific production batch, applied components, and even soldering process parameters.

How we can do it at ASZ Electronics Solutions:

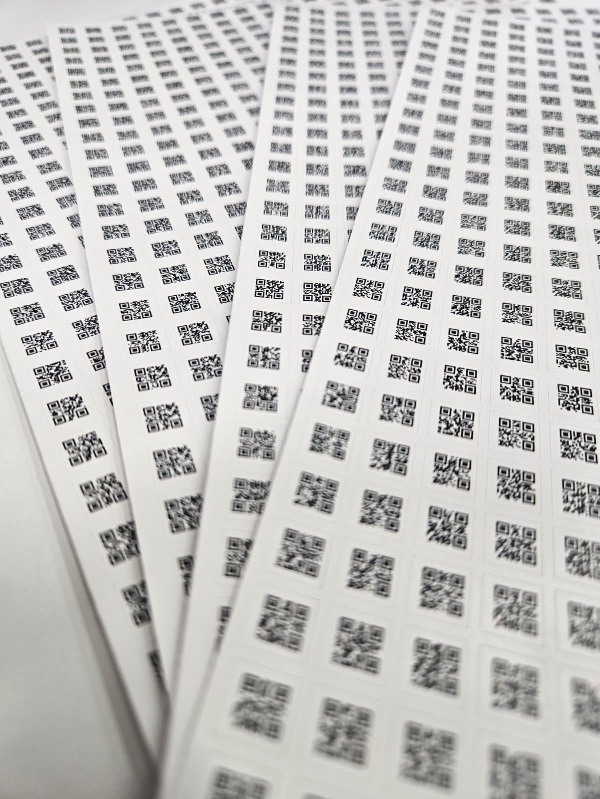

- At the customer’s request, each PCB batch can receive a unique identification code, applied as a readable text or QR code directly on the board surface.

- When full traceability is required, each module can also be marked with an individual serial number, allowing its history to be tracked – from assembly, through functional testing, to shipment.

- We can also implement a traceability system that integrates data from AOI inspection and final testing, ensuring complete control over the product lifecycle.

Why is it important?

Product marking is not just about order on the assembly line – it’s a real support tool for:

- analyzing potential nonconformities and handling complaints,

- quickly identifying components within a given batch,

- monitoring the process and maintaining compliance with IPC-A-610 standards.